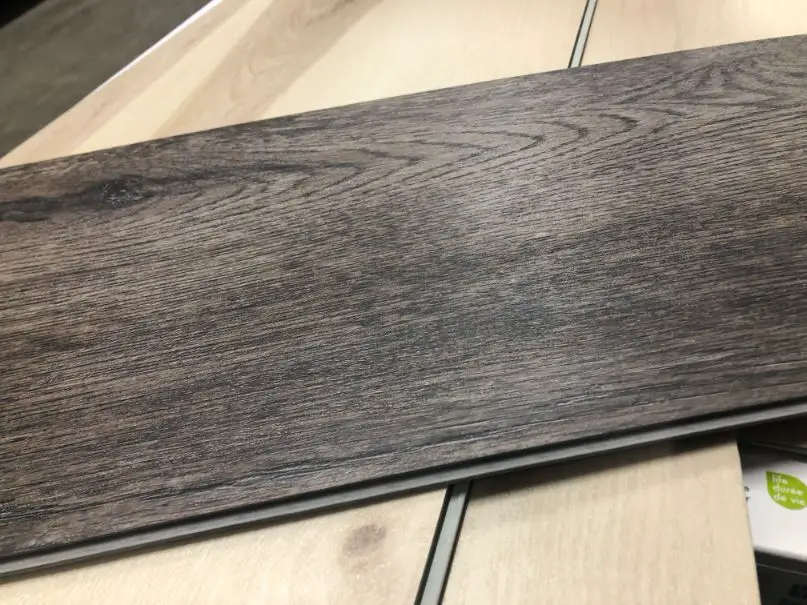

You’ve finally decided to take the plunge and upgrade your floors. You’ve chosen beautiful vinyl plank flooring, and you’re ready to get started on the installation. But wait! Before you begin cutting, there’s a crucial step you need to consider – the blade on your miter saw. The right blade can make all the difference between clean, precise cuts and frustrating, uneven edges that can ruin the look of your new floors.

Image: northmorgancreek.com

Choosing the best miter saw blade for your vinyl plank flooring project isn’t just about making the cuts; it’s about achieving a professional, seamless finish that you’ll be proud of for years to come. In this comprehensive guide, we’ll delve into the world of miter saw blades, explore the specific considerations for vinyl plank flooring, and equip you with the knowledge to choose the perfect blade for your project.

Understanding the Importance of a Good Blade for Vinyl Plank Flooring

Most people know that a sharp blade is crucial for precision cuts – that’s why woodworkers religiously sharpen their tools. But what most don’t realize is that even a well-sharpened blade might not be the right tool for every job. Vinyl plank flooring, unlike hardwood, has a distinct composition that requires a specific type of blade to prevent damage and ensure perfect cuts.

The Ultimate Guide: Choosing the Right Miter Saw Blade for Vinyl Plank Flooring

To find the right miter saw blade for your vinyl plank flooring project, you need to understand the different types of blades available and their characteristics:

1. Tooth Count: The Key to Smooth Cuts

The number of teeth on a saw blade, known as tooth count, plays a crucial role in determining the quality of your cuts, especially when working with thin materials like vinyl plank flooring. A blade with a high tooth count (around 60-80 teeth) is ideal for cutting vinyl planks because it results in:

- Smoother, cleaner cuts: The higher tooth count creates more points of contact with the material, resulting in a smoother, cleaner cut with fewer chips or burrs.

- Reduced Risk of Damage: These blades exert less pressure on the material, minimizing the chance of chipping, splintering, or damaging the delicate vinyl surface.

- Enhanced Precision: A higher tooth count blade promotes a more precise cut, which is essential for achieving tight miters and seamless transitions between flooring planks.

Image: cedarfaq.com

2. The Power of Kerf: Balancing Efficiency and Clean Cuts

Kerf refers to the width of the cut that the blade creates. Here’s how it relates to your vinyl plank flooring project:

- Thin Kerf: A thin kerf blade (0.060 inches or thinner) is commonly recommended for vinyl plank flooring.

- Why Thin Kerf Matters: A thin kerf blade minimizes material waste, allowing for more efficient use of your flooring planks. Additionally, it provides better control and accuracy, especially when making intricate cuts or tight miters.

Balancing Cutting Speed and Precision:

There’s a tradeoff between blade thickness and cutting speed. A thinner kerf blade generally means a slower cutting speed. However, the tradeoff is worth it for the added precision and smoother cuts you’ll achieve, especially when working with delicate vinyl flooring.

3. Blade Material: Impacting Durability and Performance

Several blade materials are available, each offering a unique set of properties:

- High-Carbon Steel: A popular choice for general purpose work, this blade material offers good durability at a budget-friendly price.

- Bi-Metal Blades: Known for their ability to cut through difficult materials, these blades feature a tough, hardened tooth material on a flexible steel core.

- Titanium Coated Blades: These blades are generally more expensive but offer superior performance and durability thanks to the titanium coating that enhances sharpness, prevents rust, and reduces friction.

4. Blade Type: Tailored for Vinyl Plank Flooring

The type of blade is often overlooked, yet it can significantly impact the quality of your cuts.

- Finishing Blades: This option is designed for making smooth, clean cuts without chipping or splintering, making it perfect for vinyl plank flooring.

- Combination Blades: These blades feature a combination of teeth shapes designed for both crosscutting and ripping, offering versatility for various cutting tasks.

Choosing a Blade for Your Needs:

- For general use: A combination blade can handle a wide range of cutting tasks.

- Specific vinyl plank flooring cuts: A dedicated finishing blade is your best choice for achieving smooth, clean edges.

Top Miter Saw Blades for Cutting Vinyl Plank Flooring: Informed Recommendations

To give you a starting point, here are some popular and highly-rated miter saw blades specifically designed for cutting vinyl plank flooring:

- Freud LU920010 Diablo 10-Inch Finishing Blade: This blade features a 60-tooth design and a thin kerf for smooth, clean cuts and minimal material waste. It boasts excellent durability and sharp cutting edges, making it a popular choice for vinyl plank flooring projects.

- DeWalt DW4758 10-Inch 60-Tooth Finish Blade: This blade provides a high tooth count, resulting in smooth cuts when working with vinyl plank flooring. It’s known for its durability and crisp, professional cuts.

- Bosch 10-Inch Finish Blade (10-Inch, 60 Teeth): This 60-tooth blade offers a thin kerf, delivering smooth and precise cuts that protect the delicate surface of vinyl plank flooring.

Expert Insights and Actionable Tips: Ensuring Success

Here’s your guide to using these blades effectively:

- Proper Installation: Ensure that your miter saw blade is securely installed and that the blades are positioned correctly. A correctly installed blade ensures safer operation and cleaner cuts.

- Speed Considerations: While vinyl plank flooring tends to cut more easily than hardwood, it’s essential to use appropriate cutting speeds.

- Blade Maintenance: Regularly check your blade for sharpness and damage. Dulled or chipped blades can produce rough cuts and lead to improper results. A sharp blade ensures precise, clean cuts and prolongs the life of your miter saw blade.

Best Miter Saw Blade For Cutting Vinyl Plank Flooring

https://youtube.com/watch?v=tFtBxzPLWKQ

Final Thoughts: Achieving Professional-Looking Flooring

Choosing the right miter saw blade is crucial for achieving professional-looking cuts when installing vinyl plank flooring. By understanding the different blade features, you can make an informed decision that will minimize chips, splinters, and ensure smooth, seamless transitions between your flooring planks. Remember to take care of your blades by regularly checking them for sharpness and cleaning them after use. With these tips and the right blade, you’ll be on your way to completing a flooring project you can be proud of.