Have you ever stopped to think about the simple act of moving a crate across a factory floor? It might seem like a mundane task, something easily overlooked in the grand scheme of manufacturing. Yet, this seemingly unremarkable action is a cornerstone of countless industries, a testament to the dedication and skill of countless workers. It’s a microcosm of the human spirit, a constant reminder of the tireless effort that keeps our world turning.

Image: homework.study.com

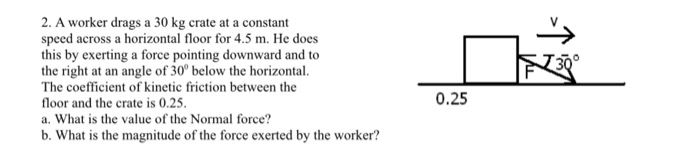

In this article, we’ll delve into the intricate world of crate-dragging. We’ll explore the various factors that impact this simple act, from the weight and dimensions of the crate to the physical demands it places on the worker. We’ll uncover the essential tools and techniques that make this seemingly mundane task both efficient and safe. We’ll also shed light on the history of this activity, tracing its evolution from the age of manual labor to the era of automated systems.

The Weight of a Crate: A Balancing Act

The very first consideration in understanding the act of dragging a crate is its weight. A seemingly harmless-looking crate can harbor a surprising amount of mass, making the process quite demanding. The weight of the crate dictates the amount of force needed to move it, affecting the worker’s physical exertion and the possibility of injury. This is where things get more complicated: the weight isn’t the only factor.

Beyond Weight: Dimensions and Distribution

The dimensions of the crate play a vital role in the dragging process. A large, unwieldy crate requires more effort and control compared to a smaller, more manageable one. The distribution of weight within the crate is equally crucial. A crate with its weight concentrated at the bottom will be easier to drag than one where the weight is unevenly distributed.

The Tools of the Trade: From Hand Trucks to Forklifts

Over time, mankind has developed numerous tools to aid in the arduous task of crate-dragging. These tools range from simple hand trucks to intricate forklift systems, each serving a specific purpose and optimizing the efficiency of this basic act.

Image: www.chegg.com

The Humble Hand Truck: An Essential Ally

The hand truck, a simple yet ingenious invention, has long been a mainstay in the factory setting. Its use requires a certain degree of manual strength and dexterity. The worker must lift the crate onto the platform and then maneuver the truck across the floor. The hand truck remains a staple for its affordability and practicality, especially for lighter crates.

The Mighty Forklift: A Mechanical Marvel

For heavier crates and larger quantities, the forklift takes center stage. This mechanized marvel revolutionized material handling, enabling swift and efficient movement of heavy objects. Forklifts are equipped with hydraulic systems that lift and transport crates with minimal human effort. The operator controls the lift and movement of the forklift, safely navigating the factory floor.

Ergonomics in Action: A Focus on Safety

The act of dragging a crate, regardless of the tool used, presents inherent physical risks to the worker. Ergonomics, the science of fitting the job to the worker, plays a crucial role in minimizing these risks.

Understanding Potential Hazards

Lifting heavy crates can strain the back and shoulders. Repeated dragging motions can lead to repetitive strain injuries in the wrists, hands, and elbows. The risk of tripping and falling increases when navigating uneven terrain or cluttered spaces. Awareness of these potential hazards is crucial for both worker safety and operational efficiency.

Implementing Safety Measures

Implementing proper lifting techniques, utilizing ergonomic tools, and ensuring clear pathways can significantly reduce these risks. Ensuring workers have proper training and are equipped with safety gear, such as back braces and safety shoes, is paramount. A proactive approach to safety is essential in minimizing workplace injuries and maximizing worker well-being.

The Impact of Automation: A Changing Landscape

The world of manufacturing is constantly evolving, with automation playing a significant role in transforming traditional processes. The act of dragging a crate has not escaped this transformation.

Automated Guided Vehicles: Navigating the Future

Automated Guided Vehicles (AGVs) are increasingly becoming integral components in modern factories. These autonomous vehicles can navigate the factory floor without human intervention, efficiently moving crates and other materials from one location to another. AGVs are particularly beneficial for repetitive tasks, freeing up human workers for more complex and creative roles.

The Future of Crate-Dragging: A Collaborative Landscape

The future of crate-dragging is likely to be a collaborative one, with humans and machines working together to optimize efficiency and safety. As automation technologies continue to advance, human workers will focus on tasks requiring higher levels of skill, critical thinking, and problem-solving.

A Worker Drags A Crate Across A Factory Floor

Conclusion: The Unseen Effort

The act of dragging a crate across a factory floor, though seemingly mundane, is a testament to human ingenuity and the relentless pursuit of efficiency. From the early days of manual labor to the era of automated systems, this simple action has evolved alongside human progress, reflecting the tireless efforts of workers who keep our world running. By understanding the complexities of this seemingly simple act, we gain a deeper appreciation for the tireless efforts that make our modern lives possible. The next time you see a worker dragging a crate across a factory floor, take a moment to acknowledge the skill, dedication, and inherent value of this essential task.