Imagine this: you’re under your car, trying to change a flat tire, and suddenly, your trusty hydraulic floor jack gives up the ghost. The handle spins freely, and the lifting arm refuses to budge. You’re stranded, frustrated, and with a flat tire to boot. This is where understanding the inner workings of a 2 ton hydraulic floor jack becomes crucial. Knowing its parts and their functions can not only help you troubleshoot problems, but also make you a more informed buyer when choosing a new jack.

Image: home.alquilercastilloshinchables.info

This article dives deep into the anatomy of a 2 ton hydraulic floor jack, providing a comprehensive parts diagram and explanations for each component. We’ll explore the principles behind its operation, common issues that arise, and offer expert tips on maintenance and troubleshooting. So buckle up, and let’s delve into the world of hydraulic floor jacks.

Understanding the Anatomy of a 2 Ton Hydraulic Floor Jack

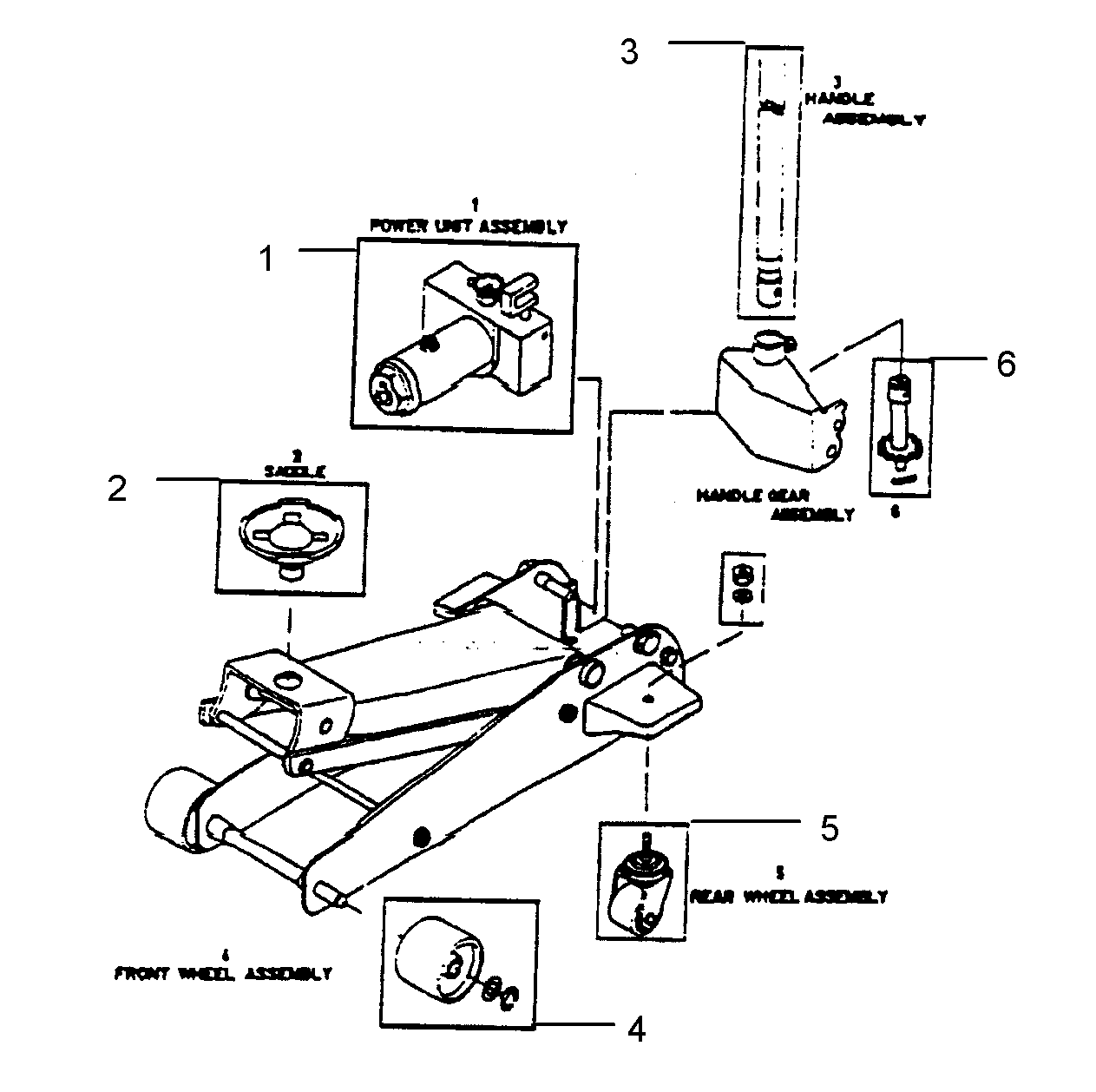

A 2 ton hydraulic floor jack, despite its simple appearance, is a marvel of engineering. Its ability to lift heavy vehicles with minimal effort relies on a carefully orchestrated interaction of individual parts. To grasp the essential components, let’s visualize a typical 2 ton hydraulic floor jack:

Key Components:

- Base Plate: The foundation of the jack, providing a stable platform for lifting. Often made of heavy-duty steel, it helps distribute weight evenly.

- Lifting Arm: This is the part that directly contacts the vehicle’s lifting point. It’s typically made of a strong metal and designed to withstand significant pressure.

- Jack Handle: The lever you use to pump hydraulic fluid into the system. The handle’s length determines how much force is required to lift the vehicle.

- Hydraulic Cylinder: The heart of the jack, containing a piston that moves up and down, powered by hydraulic fluid. This is the component responsible for lifting the vehicle, and its size determines the maximum weight capacity.

- Hydraulic Reservoir: This container stores the hydraulic fluid used to power the piston. The reservoir’s size influences the jack’s lifting stroke.

- Release Valve: This valve controls the release of hydraulic fluid, allowing the jack to lower the vehicle. It’s typically a lever or button located near the handle.

- Safety Release Mechanism: Some jacks have a safety release mechanism, preventing accidental lowering of the vehicle. This can be a pin, a lock, or a similar safety feature.

- Lifting Saddle: A metal plate at the end of the lifting arm that creates a wider surface area to distribute the load on the vehicle.

How the Hydraulic System Works

The workings of a hydraulic floor jack are all about the principles of hydraulics. These principles state that pressure exerted on a confined liquid is transmitted equally to all points within the liquid. This is best understood by considering the interaction between the jack handle, hydraulic cylinder, and release valve.

Imagine the jack handle as a pump. When you push down on the handle, it forces hydraulic fluid through a one-way valve (often called a check valve) into the hydraulic cylinder. This increases the pressure within the cylinder, pushing the piston upward. The piston is connected to the lifting arm, causing the arm to rise and lift the vehicle.

To lower the vehicle, you simply open the release valve. This allows the hydraulic fluid to flow back into the reservoir, reducing the pressure in the cylinder. The piston then descends, lowering the lifting arm and the vehicle.

Image: surferpix.com

Common Issues & Troubleshooting

Like any mechanical device, hydraulic floor jacks can experience problems. Recognizing these issues and knowing how to troubleshoot them can save you time, frustration, and avoid potential dangers.

Common Problems:

- Slow Lifting Action: This usually indicates a leak in the hydraulic system, possibly at the seals of the cylinder, the release valve, or the hose connecting the handle to the cylinder.

- Jack Won’t Lift: This could be due to air in the hydraulic system (requiring a bleeding procedure), a faulty pump, or a jammed lifting arm.

- Jack Won’t Lower: This typically points to a stuck or damaged release valve.

- Noise During Operation: A grinding noise could signal a worn-out pump or a problem with the cylinder.

Maintenance & Expert Tips

Regular maintenance is vital for ensuring your hydraulic floor jack operates smoothly and safely. Here are some expert tips to prolong the life of your jack:

Expert Tips:

- Keep it Clean: Regularly clean the jack with a damp cloth to remove dirt and debris that can accumulate and impede its function.

- Inspect the Seals: Inspect the seals around the hydraulic cylinder, release valve, and pump for signs of wear or damage. Replace any damaged seals promptly.

- Check Fluid Level: Make sure the hydraulic fluid level is topped off. Top it up with the appropriate fluid according to the manufacturer’s recommendations.

- Avoid Overloading: Never exceed the jack’s rated capacity. Overloading can damage the hydraulic system and pose a safety hazard.

- Store Properly: Store the jack in a clean, dry place to prevent corrosion.

- Consider Lubrication: Apply a light layer of lubricant, like silicone spray, to the moving parts to reduce friction and wear.

FAQ

Q1: What is the difference between a 2 ton and a 3 ton hydraulic floor jack?

The main difference is their weight capacity. A 2 ton jack can lift up to 2 tons (4,000 lbs), while a 3 ton jack can lift up to 3 tons (6,000 lbs). Choose a jack with a weight capacity that exceeds the weight of your vehicle.

Q2: How often should I check my hydraulic jack for leaks?

It’s recommended to check your jack for leaks at least once a year or before every use. Look for any signs of fluid leaks around the cylinder, release valve, or pump. If you find any leaks, address them promptly to prevent further damage.

Q3: Can I use any hydraulic fluid in my jack?

No, it’s essential to use the correct type of hydraulic fluid specified by the manufacturer. Using the wrong fluid can damage the seals and hydraulic components.

Q4: How do I bleed the air out of the hydraulic system?

Bleeding air from the hydraulic system is usually achieved by opening a bleed screw (a small screw) located on the cylinder. This allows air to escape while the jack is operated. Consult your jack’s manual for specific instructions and location of the bleed screw.

2 Ton Hydraulic Floor Jack Parts Diagram

Conclusion

Understanding the components and workings of a 2 ton hydraulic floor jack is crucial for any DIY enthusiast or anyone who works on their own vehicles. By familiarizing yourself with the parts, potential issues, and maintenance tips, you can ensure your jack operates reliably and safely for years to come. So, are you ready to confidently tackle your next car repair project with a well-maintained hydraulic jack?