As a business professional working with SAP, you’ve likely encountered the term “MIGO.” But have you ever stopped to truly understand what it signifies within the vast SAP ecosystem? This acronym, which stands for “Material Goods Movement,” plays a crucial role in managing materials within your organization. But what exactly does it entail?

Image: arielferskrueger.blogspot.com

In this blog post, we’ll delve into the world of MIGO, uncovering its significance, functionality, and applications within SAP. We’ll explore its history, the various transactions it encompasses, and the latest trends in utilizing MIGO. Get ready to gain a deeper understanding of this essential SAP component and how it can optimize your material management processes.

What is MIGO and its Significance in SAP?

MIGO is a core transaction code in SAP MM (Materials Management) responsible for managing the movement of materials within your system. It serves as a central hub for various material-related transactions, allowing you to record and track the flow of goods from receipt to shipment.

Think of MIGO as the control tower for your warehouse operations. It provides visibility into the entire material lifecycle, from the initial receipt of goods to their final destination. By accurately recording every movement, MIGO ensures that your inventory data is accurate and reliable. This accuracy is crucial for making informed decisions regarding procurement, production, and sales.

Understanding the Functions of MIGO

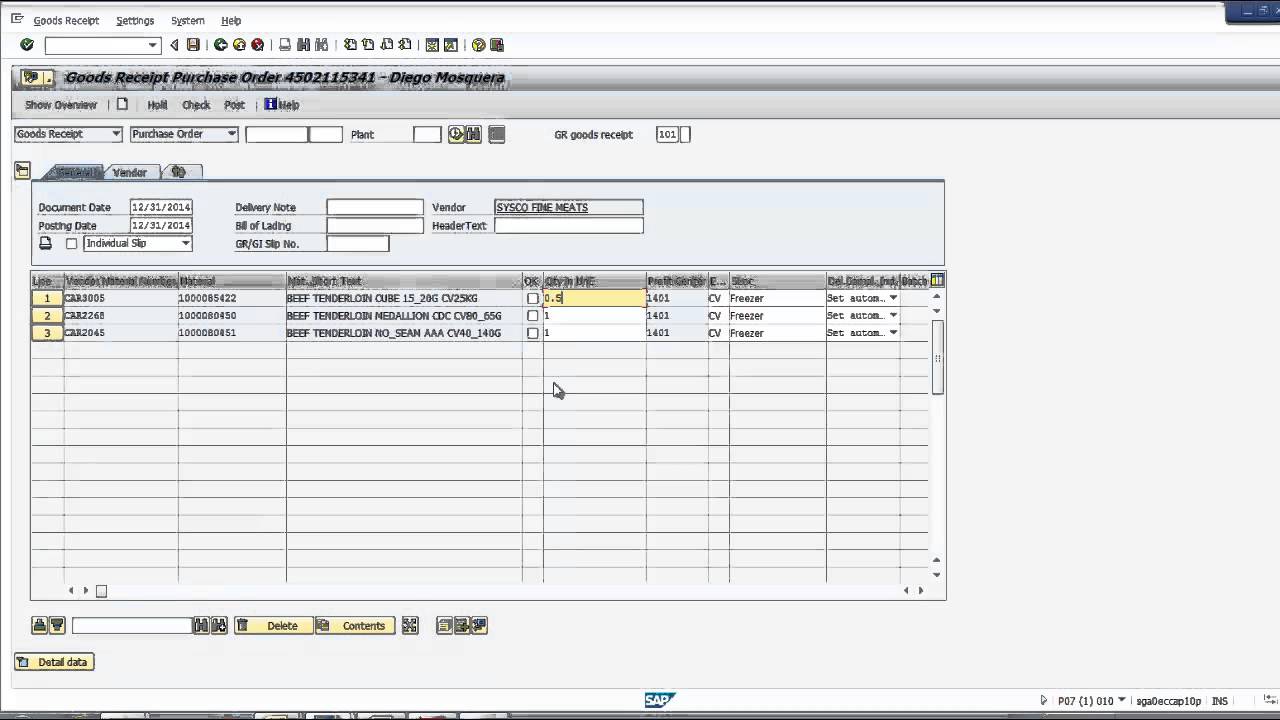

Receipt of Goods (Goods Receipt PO)

One of the primary functions of MIGO is to document the receipt of goods against a purchase order (PO). This involves recording the quantity received, the date of receipt, and any differences with the ordered quantity. MIGO allows you to track discrepancies and ensure that your procurement processes are efficient.

Image: analiticaderetail.com

Transfer Posting

MIGO facilitates the transfer of materials from one storage location to another within your warehouse. This could involve moving goods from the receiving area to the storage area, or from one production area to another. By documenting these movements, MIGO maintains accurate inventory levels in each location.

Goods Issue (Goods Issue PO)

When goods are consumed for production, sales, or other purposes, MIGO records the goods issue. This involves deducting the consumed quantity from your inventory. MIGO helps track material consumption, ensuring that your production planning is based on accurate data.

Further Exploring MIGO’s Functionality

Scrap and Return

MIGO allows you to record the scrapping of defective materials or the return of unused goods to your supplier. This enables you to manage waste, track returns, and ensure that your inventory data remains accurate.

Inventory Adjustment

MIGO provides the capability to adjust inventory levels if discrepancies are detected between the physical inventory and the system data. This allows for manual adjustments to ensure that your inventory records reflect the actual stock quantities.

Production Activities

MIGO integrates with SAP’s Production Planning (PP) module. You can use MIGO to record materials used in production processes, such as raw materials, components, and finished goods.

Tips and Expert Advice for Effective MIGO Usage

Here are some expert tips for maximizing the efficiency of your MIGO processes:

- Maintain Accurate Master Data: Ensure that your material master data is up-to-date and accurate to avoid errors during MIGO transactions. Incorrect material data can lead to inaccurate inventory records and discrepancies in your material flow.

- Use Barcode Scanning: Utilize barcode scanners to speed up the recording of material movements and minimize manual data entry errors. This significantly improves the efficiency of your MIGO processes.

- Implement Stock Taking Regularly: Conduct regular physical stock takes to verify the accuracy of your inventory levels. This helps identify any discrepancies and allows you to prompt adjustments through MIGO.

- Automate MIGO Transactions: Explore the option of automating repetitive MIGO transactions using custom programs or workflows. This can significantly free up your team’s time and reduce the risk of errors.

- Train Your Team: Provide adequate training to your team on how to accurately utilize MIGO. Ensure they understand the various transactions and relevant business processes.

By following these tips, you can ensure that your MIGO activities are streamlined, accurate, and contribute to the overall efficiency of your material management processes.

FAQ: Understanding MIGO and its Uses

Here are some common frequently asked questions about MIGO in SAP:

Q: What are the key benefits of using MIGO?

A: MIGO provides several key benefits, including:

- Accurate inventory data: MIGO ensures that your inventory records reflect the real-time status of your materials.

- Improved material flow tracking: MIGO allows you to track the movement of materials across your entire supply chain.

- Enhanced operational efficiency: MIGO simplifies material management processes, reducing manual effort and potential errors.

Q: What are some common errors users might encounter while using MIGO?

A: Common errors include:

- Incorrect material master data

- Insufficient stock availability

- Missing or inaccurate material documents

Q: How can I troubleshoot issues with MIGO transactions?

A: To troubleshoot MIGO issues, review your transaction logs, check the material master data, and verify the availability of materials. You can also consult SAP documentation or seek assistance from an SAP expert.

Q: Are there any alternatives to using MIGO?

A: While MIGO is a standard SAP transaction, other options for material management exist, such as custom developed programs or third-party solutions.

Migo Means In Sap

https://youtube.com/watch?v=MZ6xSsTOLtY

Conclusion: MIGO – a Vital Component for Efficient Material Management

In conclusion, MIGO plays a crucial role in ensuring accurate and efficient material management within your SAP system. By understanding its functions, functionalities, and best practices, you can optimize your material flow processes and gain greater control over your inventory data.

Are you interested in learning more about MIGO and its applications in your specific industry? Share your thoughts in the comments below!