Imagine a skyscraper, soaring high above the city skyline. What holds its floors together, allowing them to span vast distances and support immense weight? The answer: post-tensioned concrete. This innovative technique revolutionizes floor design, transforming ordinary concrete into a powerful, adaptable, and efficient structural element.

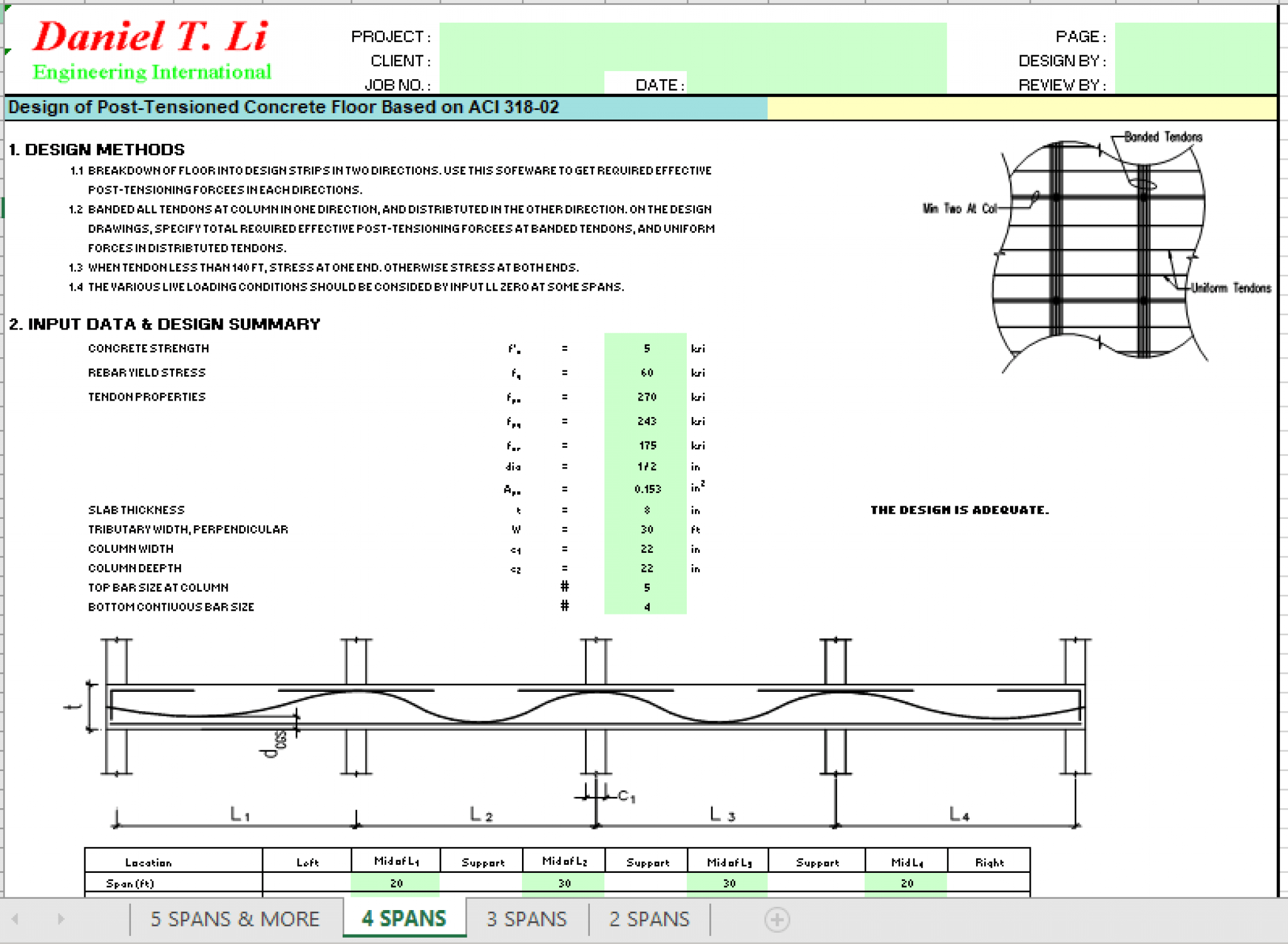

Image: excel.civilmdc.com

Post-tensioned concrete floors are not just a modern marvel – they’re a testament to clever engineering ingenuity. While most people associate concrete with basic construction, post-tensioning opens up a whole world of possibilities, enabling engineers to create longer spans, thinner slabs, and stronger structures. But how does it work?

Understanding Post-Tensioning

The Essence of Post-Tensioning

Post-tensioning is a specialized technique used to enhance the strength and durability of concrete floors. Unlike traditional reinforced concrete, which relies on steel embedded within the concrete, post-tensioned floors employ high-strength steel cables that are stretched and anchored after the concrete has hardened. This process creates compressive stress within the concrete, effectively counteracting the tensile forces that cause cracks and failures.

This method offers several advantages:

- Increased Span Capacity: Post-tensioned floors can span significantly greater distances than traditional concrete floors, allowing for open and flexible spaces.

- Reduced Slab Thickness: By minimizing the need for thick, cumbersome slabs, architects can achieve more elegant and efficient designs.

- Enhanced Durability: The compressive forces from the tensioning process significantly improve the concrete’s resistance to cracking and deformation.

- Lightweight Construction: The thinner slabs and reduced reinforcement requirements contribute to a lighter structure, leading to potential cost savings and reduced foundation loads.

Key Components

Understanding the components of a post-tensioned floor is crucial:

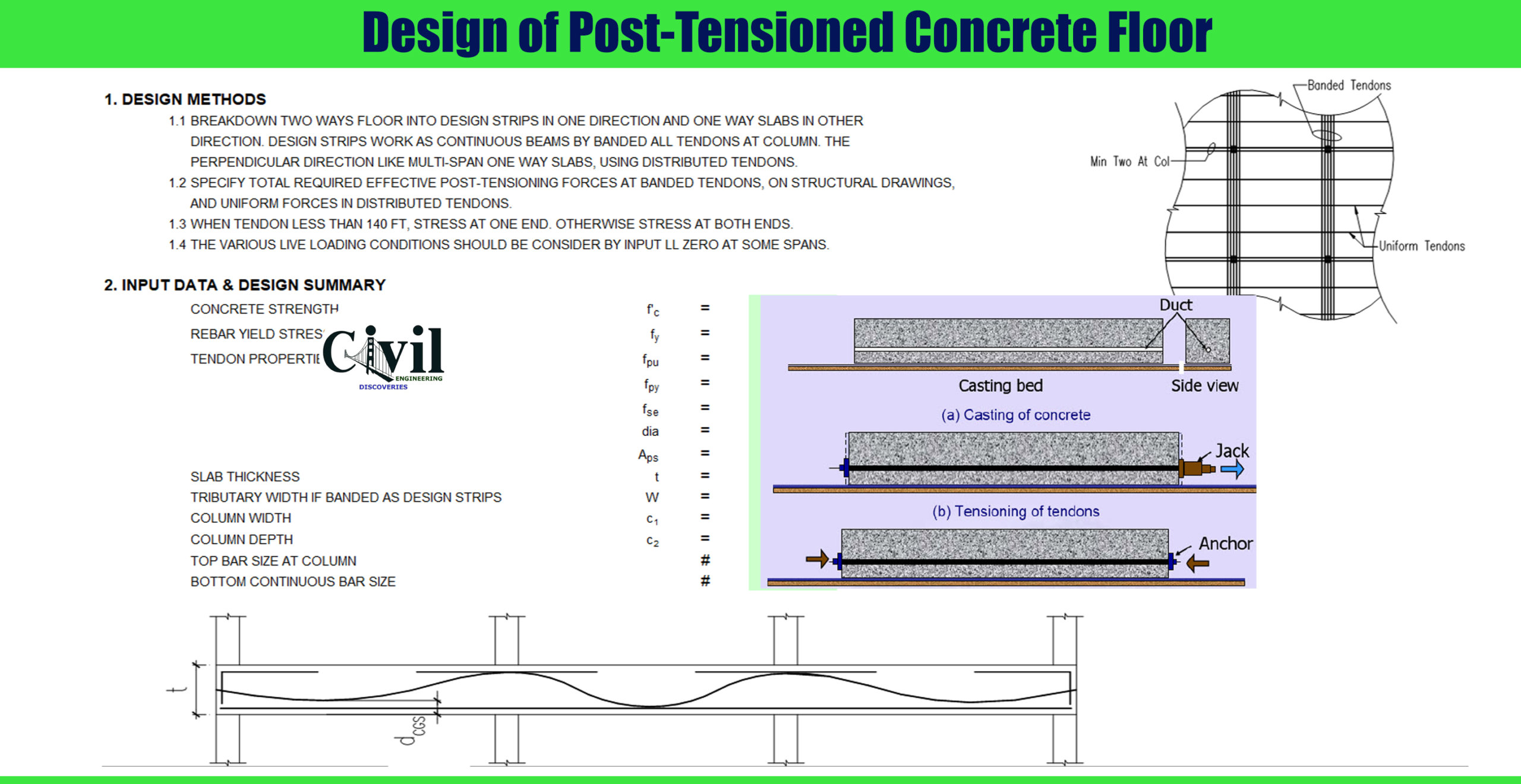

- Tendons: These high-strength steel cables are the heart of the post-tensioning system. They are encased in sheaths or ducts that run through the concrete slab.

- Anchorage: At the ends of the tendons, anchors secure the cables, creating the necessary tension.

- Jacking System: A specialized jacking system is used to stretch the tendons after the concrete has cured, creating the required compressive force within the slab.

Image: engineeringdiscoveries.com

Design Fundamentals of Post-Tensioned Concrete Floors

1. Structural Analysis and Load Considerations

The design of a post-tensioned concrete floor begins with a comprehensive structural analysis. Engineers meticulously consider the intended use of the floor, the anticipated live and dead loads, and environmental factors such as temperature variations and seismic activity. This comprehensive analysis ensures that the floor can withstand the stresses it will encounter during its lifetime.

2. Tendon Spacing and Configuration

The placement, spacing, and configuration of the tendons are crucial for achieving optimal stress distribution within the concrete slab. Engineers carefully calculate tendon paths to ensure that the tensioning force is applied in a manner that minimizes potential cracks and maximizes the load-carrying capacity.

3. Anchoring and Grouting

Anchoring systems secure the tendons at their ends, transferring the tensioning force to the concrete slab. Grouting, a high-strength cement slurry, is injected into the sheaths or ducts around the tendons. This grout serves multiple purposes: it provides corrosion protection for the tendons, enhances bond strength between the tendons and concrete, and ensures uniform stress distribution.

4. Pre-Stressing Force Calculation

Determining the appropriate pre-stressing force is crucial for the effective design of the post-tensioned floor. This force is calculated based on the anticipated loads, the properties of the concrete and steel, and the desired level of stress within the slab. An insufficient pre-stressing force can compromise the structural integrity of the floor, while excessive force can lead to premature cracking.

5. Deflection and Crack Control

Post-tensioning effectively limits deflections (the amount of downward movement) and minimizes the likelihood of cracking. The tensioning force creates compressive stresses that resist the tensile forces responsible for these issues. However, engineers must carefully account for these factors during design to ensure that the floor behaves as intended under various loading conditions.

Trends and Innovations in Post-Tensioned Concrete Floors

Post-tensioning is a dynamic field driven by ongoing research and technological advancements. Here are emerging trends shaping the future of this technology:

- High-Performance Concrete: Advances in concrete technology are yielding new materials with improved strength, durability, and sustainability. Integrating these materials into post-tensioned floors further enhances their structural performance.

- Smart Tensioning Systems: Cutting-edge sensors and monitoring systems are being incorporated into post-tensioning systems. These systems allow engineers to remotely track and manage tensioning processes, optimizing performance and ensuring long-term reliability.

- Sustainable and Eco-Friendly Solutions: The industry is embracing sustainable practices, using recycled materials, reducing embodied carbon, and exploring innovative approaches to minimize the environmental impact of post-tensioned construction.

Design Tips and Expert Advice

As a blogger and someone who has followed the post-tensioned floor industry closely for years, here are a few essential tips and expert advice for those considering this design approach:

- Collaborate with Experienced Experts: The design and construction of post-tensioned floors require expertise in structural engineering, concrete technology, and post-tensioning practices. It’s essential to work with experienced engineers, contractors, and specialists who can ensure the project is executed to the highest standards.

- Thorough Planning and Documentation: Detailed planning and thorough documentation are critical throughout the post-tensioning process. Clear communication and documentation ensure that all parties involved understand the construction sequence, material specifications, and the expected performance of the finished floor.

- Consider Life-Cycle Costs: While initial costs for post-tensioned floors can be higher than traditional concrete solutions, their long-term durability and reduced maintenance needs can offset these costs over the life of the structure.

FAQs

Q: What are the common applications of post-tensioned concrete floors?

A: Post-tensioned concrete floors are extensively used in various structures, including:

- High-rise buildings

- Parking garages

- Bridges

- Stadiums and arenas

- Industrial facilities

- Large-span commercial buildings

Q: What are the challenges associated with post-tensioned concrete floors?

A: While post-tensioned floors offer several advantages, they also present certain challenges:

- Complex Design and Construction: Post-tensioning involves intricate calculations, specialized equipment, and precise execution, requiring experienced professionals.

- Cost Considerations: Initial costs for post-tensioned construction can be higher compared to traditional methods.

- Potential Corrosion: While grouting helps prevent corrosion, long-term exposure to moisture and aggressive environments can still pose a risk to the tendons.

Design Fundamentals Of Post Tensioned Concrete Floors

Conclusion

Post-tensioned concrete floors are a testament to the innovative spirit of modern engineering. By harnessing the power of pre-stressing, this technique delivers remarkable strength, durability, and flexibility for a wide range of structures. Understanding the design fundamentals, embracing emerging trends, and seeking expert guidance will ensure that your next project leverages the full potential of this advanced construction method.

Are you interested in learning more about the engineering marvels of post-tensioned concrete floors? Share your questions and thoughts in the comments below!